Thermal transfer film for thermal transfer. Thermal film for fabric

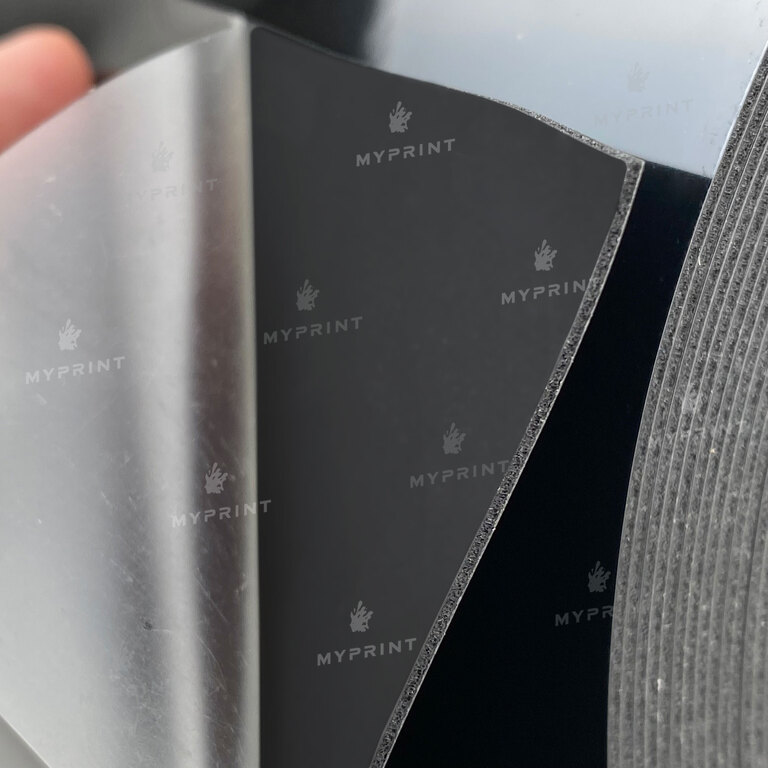

Thermal transfer film is a great alternative to paper for thermal transfer. Made of polyvinyl chloride or polyurethane coated with a layer of thermally activated adhesive, it is very flexible and comfortable to use.

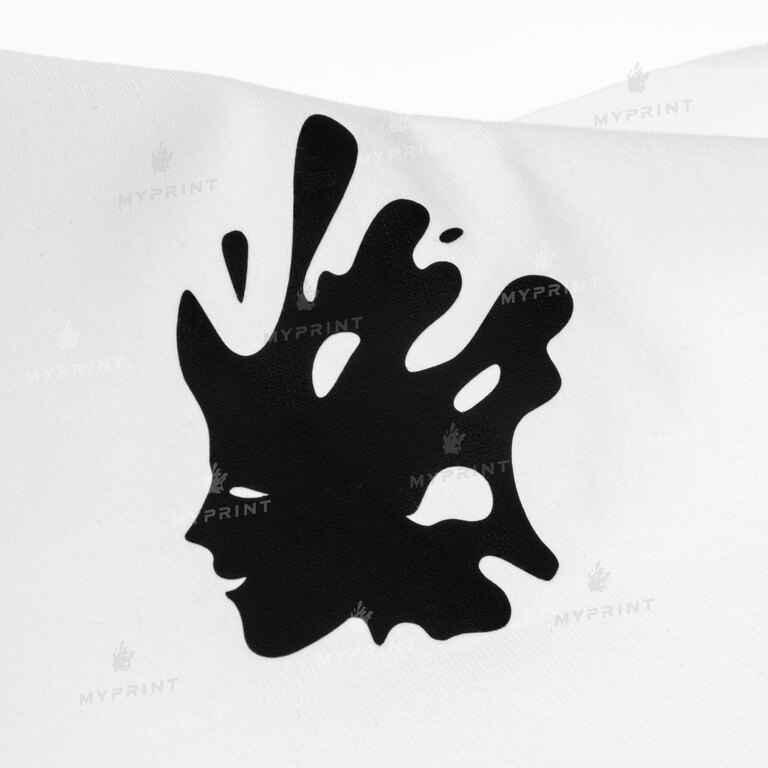

![Thermal transfer film My Print High Flex PU white 1 pc. m. (1*0.5 m) (7214) Thermal transfer film My Print High Flex PU white 1 pc. m. (1*0.5 m) (7214)]()

![Thermal transfer film My Print High Flex PU white 1 pc. m. (1*0.5 m) (7214) Thermal transfer film My Print High Flex PU white 1 pc. m. (1*0.5 m) (7214)]() Top sellersIn stock

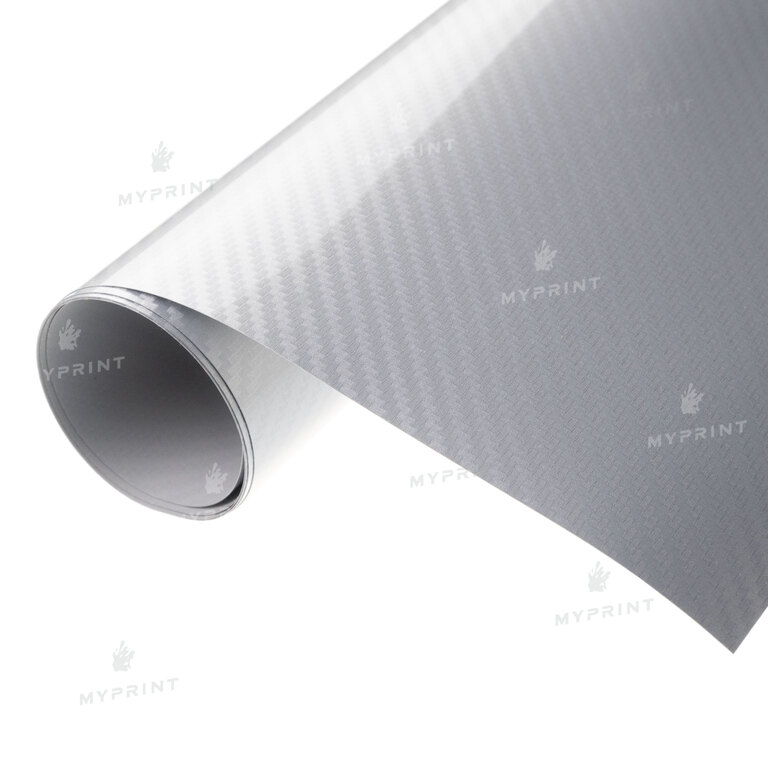

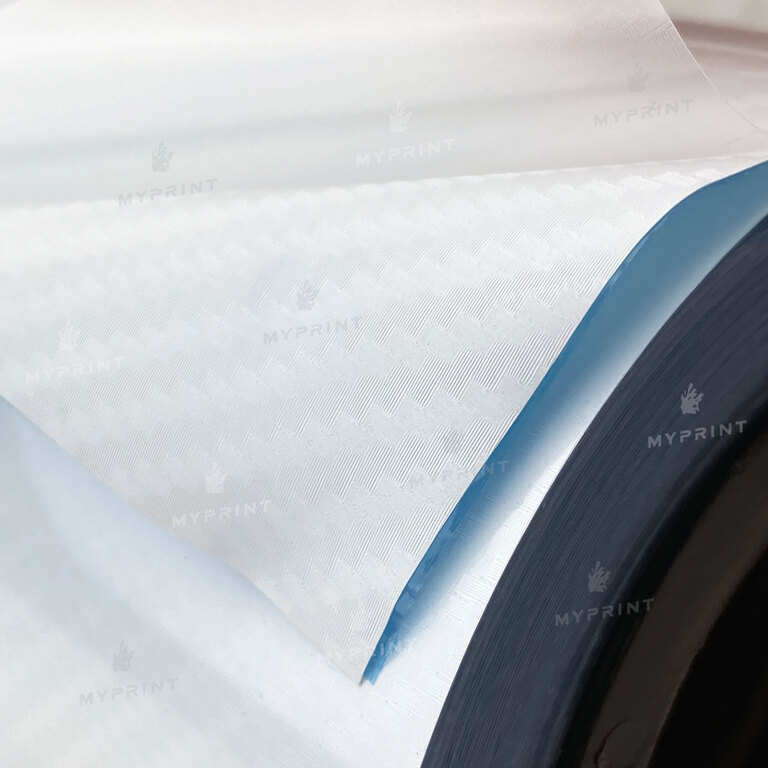

Top sellersIn stock- Type:PU

- Color:White

- Feature:A substrate with an adhesive layer

- Width:0.5 m

- Transfer temperature:150-160 °C

- Transfer time:10-15 seconds

- Pressure:Average

- Removing the lining:On a cold one

- Knife sharpening angle:45°

- Thickness:0.09 mm

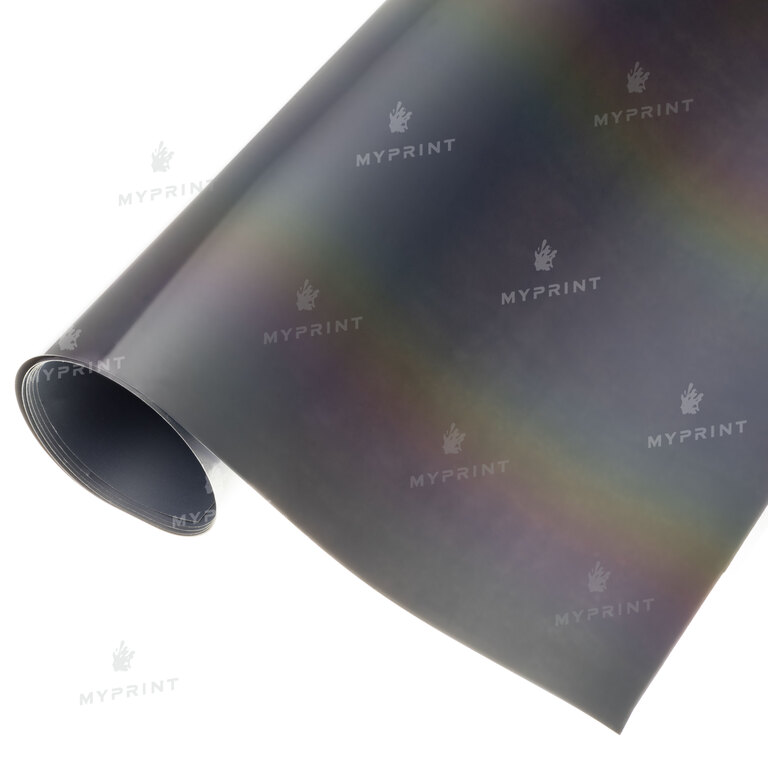

![Thermal transfer film My Print High Flex PU black 1 pc. m. (1*0.5 m) (7213) Thermal transfer film My Print High Flex PU black 1 pc. m. (1*0.5 m) (7213)]()

![Thermal transfer film My Print High Flex PU black 1 pc. m. (1*0.5 m) (7213) Thermal transfer film My Print High Flex PU black 1 pc. m. (1*0.5 m) (7213)]() Top sellersIn stock

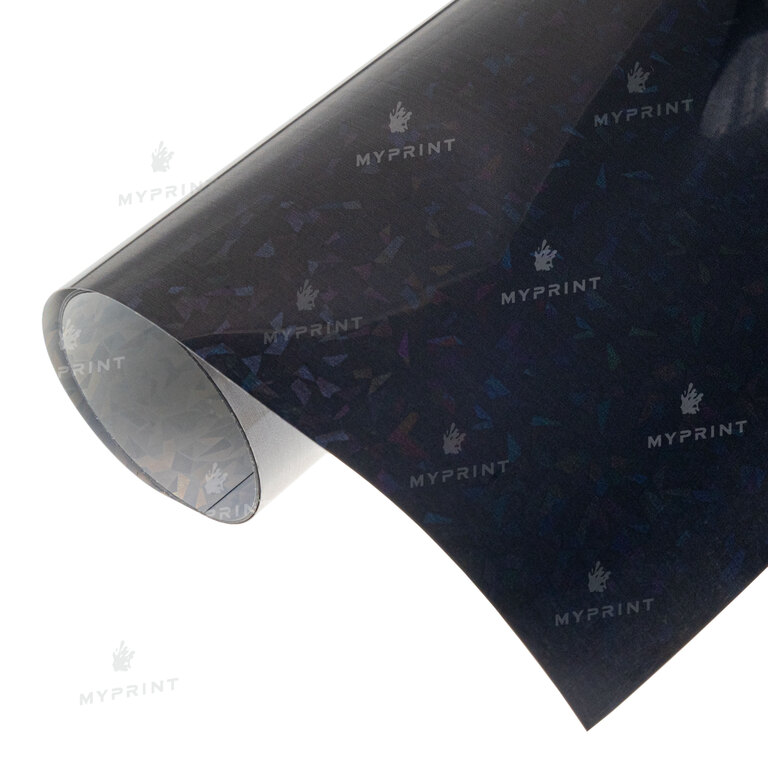

Top sellersIn stock- Type:PU

- Color:Black

- Feature:A substrate with an adhesive layer

- Width:0.5 m

- Transfer temperature:150-160 °C

- Transfer time:10-15 seconds

- Pressure:Average

- Removing the lining:On a cold one

- Knife sharpening angle:45°

- Thickness:0.09 mm

![Thermal transfer film My Print Sublifabric for sublimation printing Flock short 1 pg. m. (1*0.5 m) (7678) Thermal transfer film My Print Sublifabric for sublimation printing Flock short 1 pg. m. (1*0.5 m) (7678)]()

![Thermal transfer film My Print Sublifabric for sublimation printing Flock short 1 pg. m. (1*0.5 m) (7678) Thermal transfer film My Print Sublifabric for sublimation printing Flock short 1 pg. m. (1*0.5 m) (7678)]() In stock

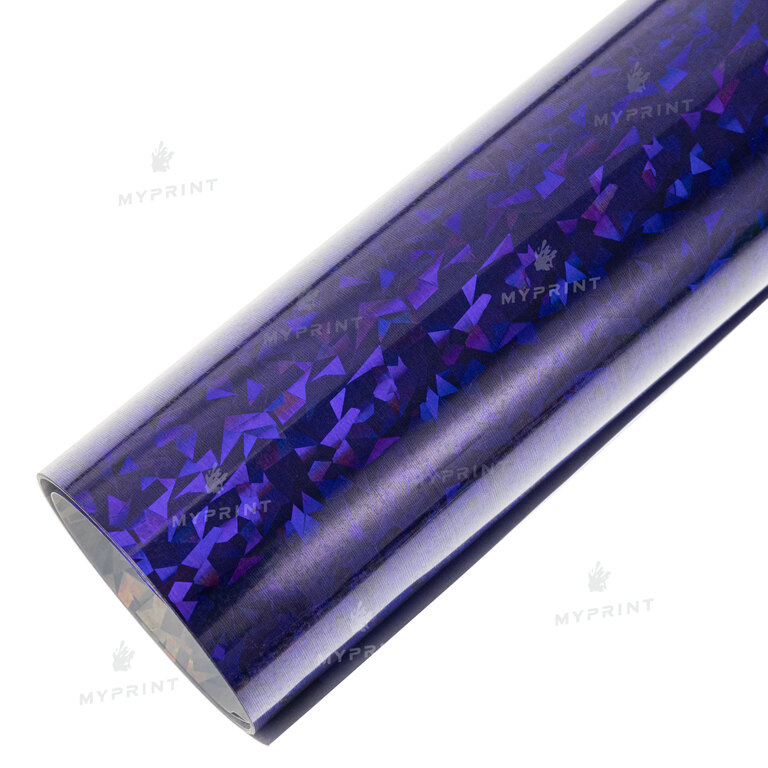

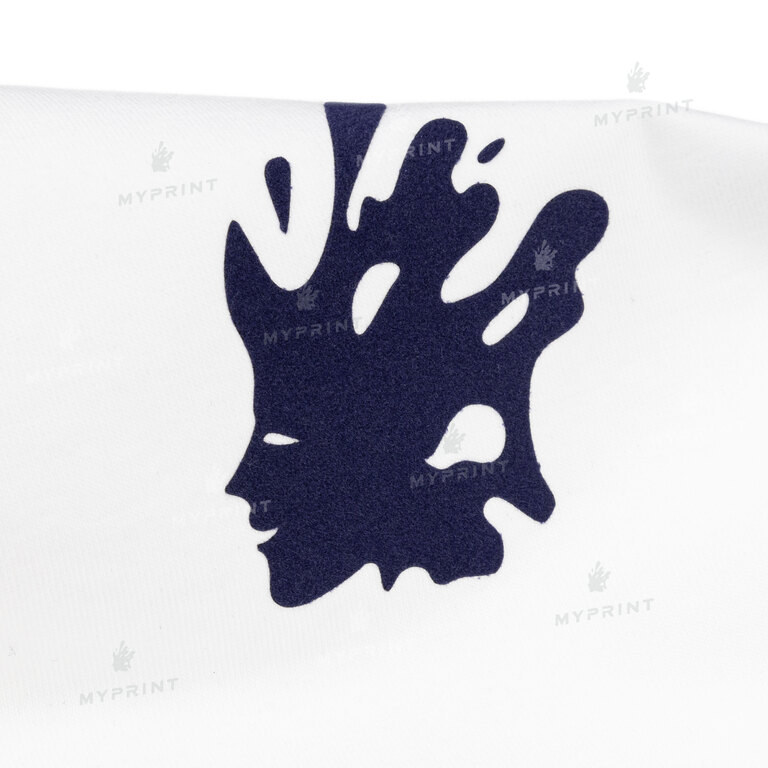

In stock- Type:Sublifabric

- Kind:Thermal transfer film

- Color:For printing

- Surface:Flock short

- Size:1*0,5 m

- Feature:A substrate with an adhesive layer

- Quantity per package:1

- Format:Roll

- Width:0.5 m

- To transfer to:All fabrics

- Print type:Sublimation

- Transfer temperature:185-195 °C

- Transfer time:40 sec

- Pressure:Average

Advantages of thermal transfer film

Thermal film has numerous advantages that have already been appreciated by owners of sublimation equipment.

The main advantages include:

Convenience of application to the blank;

Thermal transfer film combines well with most types of fabrics (cotton, synthetic, mixed type) regardless of their composition or color scheme;

High resistance to high temperatures, which is manifested by a minimal percentage of deformation at the moment of placing the film with the image applied to it in a heat press;

Elasticity of the image for a long time after application;

High resistance of the applied image;

Excellent image quality, clarity of lines and brightness of colors;

Maximum possible level of dye penetration into the fabric fibers;

Guarantees softness of the image.

Thermal transfer film is cut using a plotter. Other methods and tools, unfortunately, are not suitable. Only in this way will you get the perfect cut of the required size.

Thermal film - usage features

Anyone can cope with applying a printed image on the fabric using thermal film, as the procedure is very simple. The main thing is to follow a certain sequence of actions:

Print the selected image in reverse on a printer filled with special ink.

Attach the film to the fabric with the print facing down and fix it with special heat-resistant tape.

Place the product in a heated heat press, covering it with protection in the form of tracing paper, silicone paper or other lining.

The time of the heat press operation usually does not exceed 15-30 seconds.

Remove the cooled product from the heat press and carefully remove the lining from it.

What types of thermal transfer film are there?

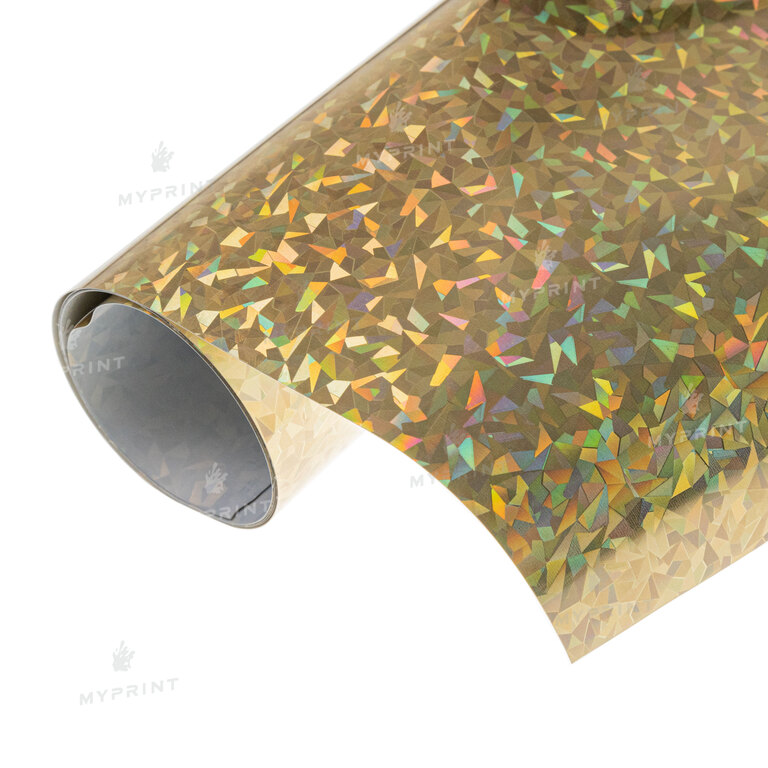

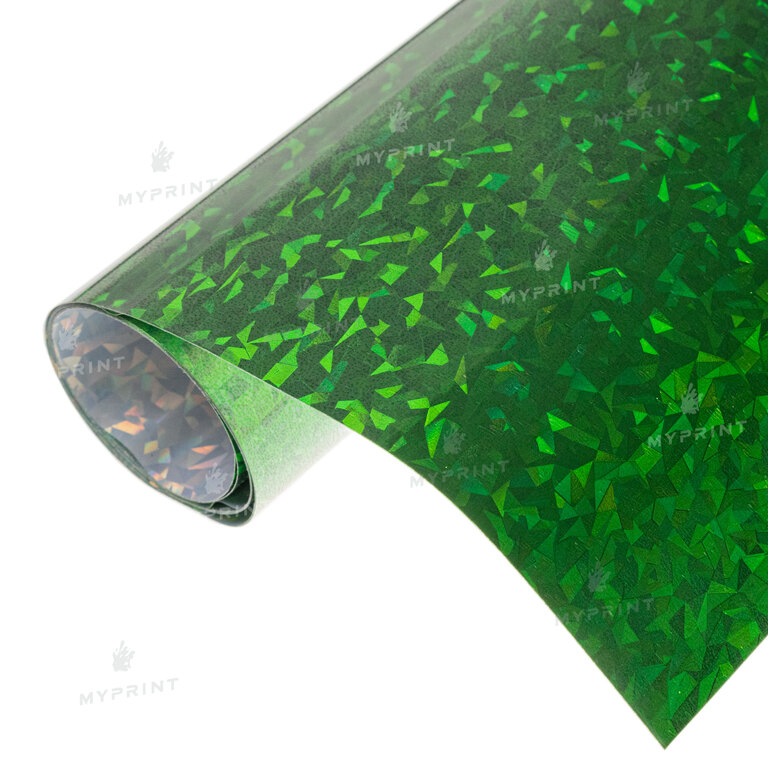

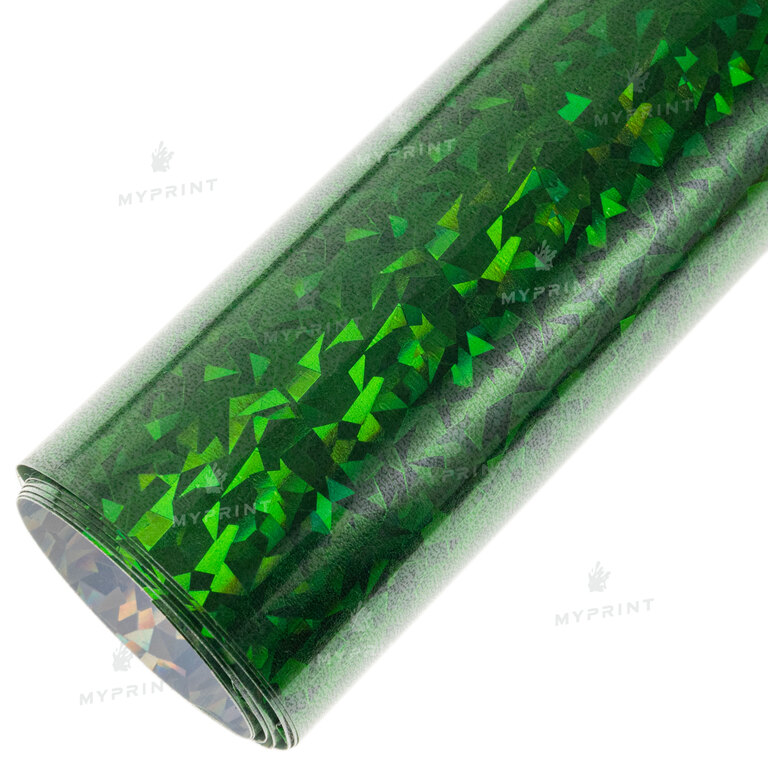

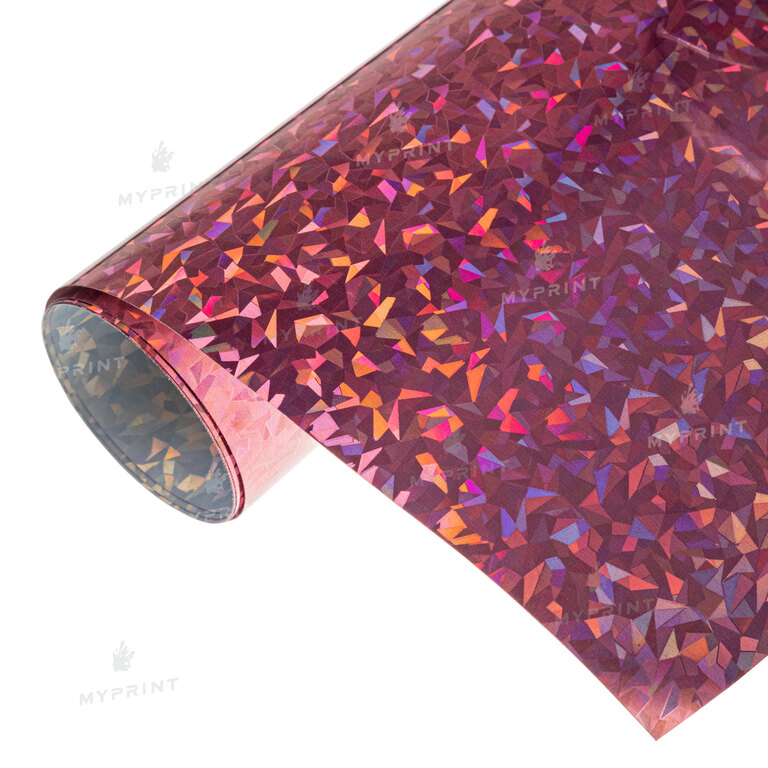

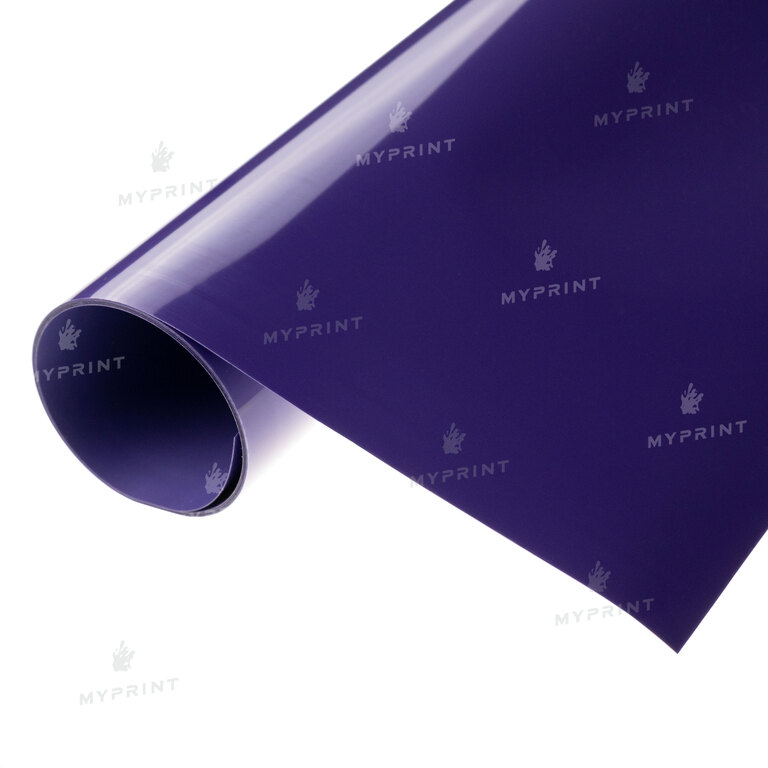

Generally, films differ in thickness, width, color, presence of patterns, and surface type (solid, mesh).

We offer high-quality thermal transfer film of various types for fabric:

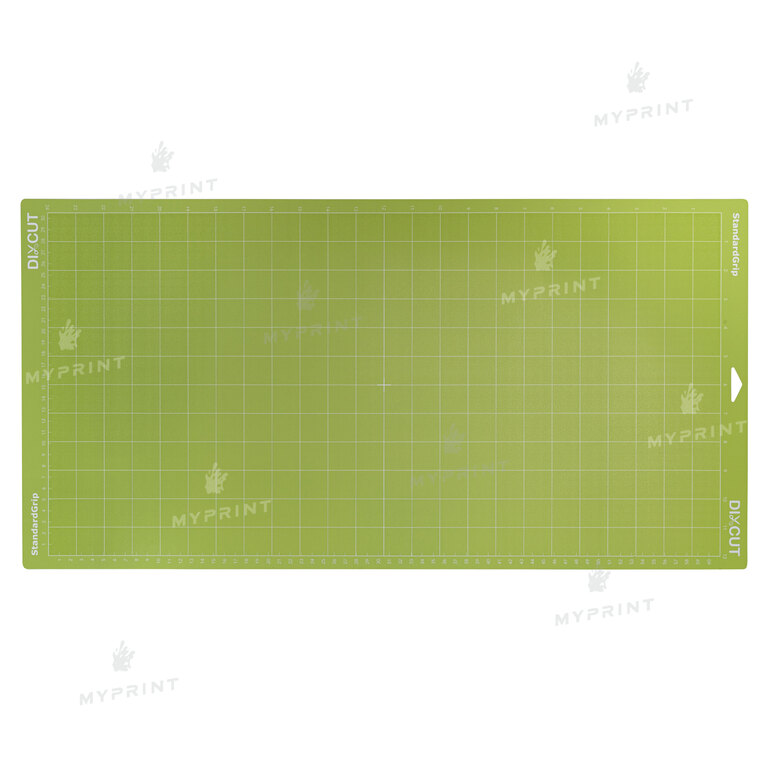

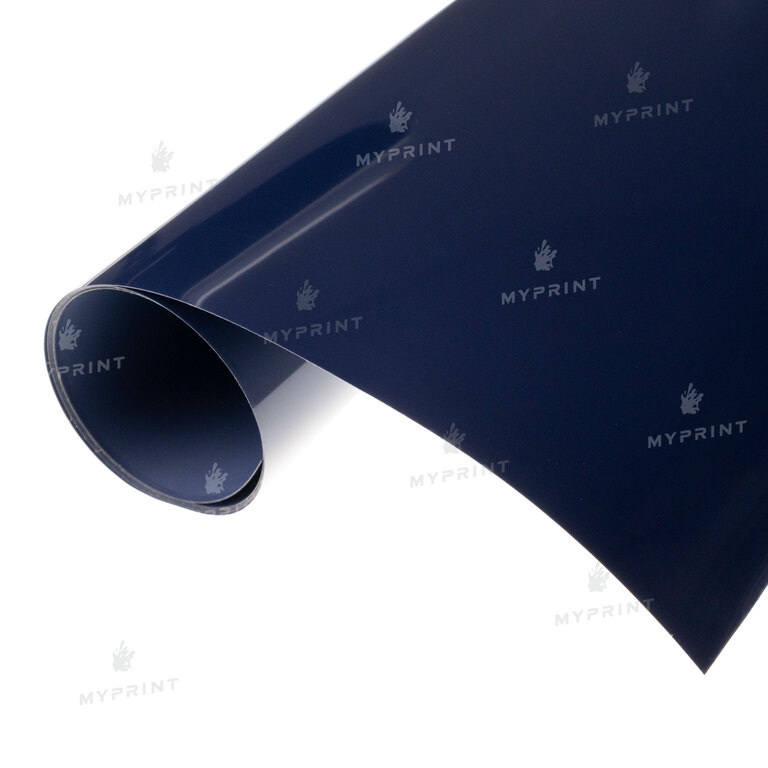

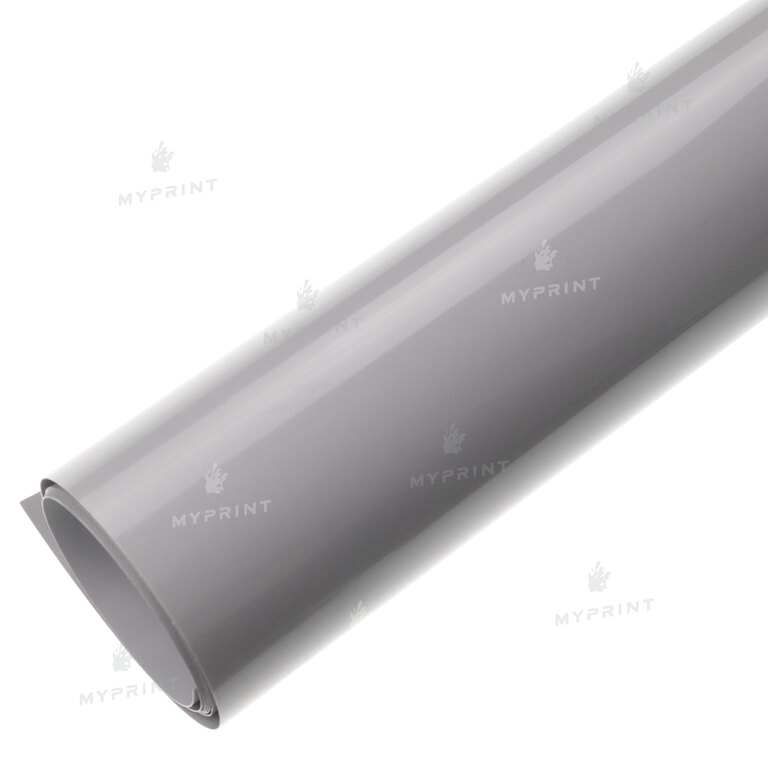

Flex PU. This thermal film is made of polyurethane and has a matte surface. It is a highly elastic flex film. Suitable for working with 100% cotton, 100% polyester, and their blends. The thermal transfer flex film is coated with a layer of special thermoadhesive, which is activated when heated and firmly connects the thermal film and the fabric. Thanks to the self-adhesive backing, it is convenient to work with small details and position the prepared transfer on the product. This thermal transfer film can be used on any type of plotter. The thickness of the thermal transfer film is only 90 µm.

PVC - allows you to apply images to cotton, synthetic, and mixed fabrics. The thermal film has high stretchability.

PU for printing with eco-solvent white ink, which allows it to be applied to material of any color. Before applying to the fabric, it is necessary to remove the areas of white color where the image was not printed.

Flock - white, designed for color and monochrome images. It can be compared to velvet fabric. Such images look voluminous, natural, and very beautiful.

A few tips for buyers

If you are not sure which thermal transfer film is suitable for your tasks, call our consultants. We will not only select the optimal option for you but also tell you about the features of using this consumable material and existing limitations.

Remember that to ensure the longest possible service life of the finished product, it is not recommended to wash it within the first 24 hours after applying the image.

To ensure that the image lasts as long as possible and does not lose its quality characteristics, the water temperature during washing should not exceed 60ºC.

FAQ about "Thermal transfer film":

We suggest you familiarize yourself with the offers from the following categories:

We recommend paying attention to the following products: